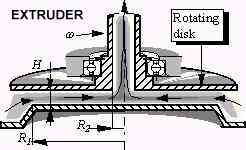

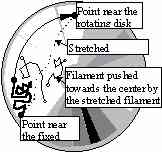

This has nothing to do with inertial forces. Centripetal flow is induced by normal stresses arising in a sheared elastic liquid (nothing like that happens in common liquids, such as water, oils and molten metals). The driving pressure increases with the rotational speed of the upper disk w, and with the decreasing width of the gap, H, (Dp»w2/H2). It would not be a good idea to start an explanation of this phenomena by introducing, e.g., the Maxwell model describing the behaviour of viscoelastic polymers. It would involve solving some very complicated equations for the pressure and velocity field, Leonov (1994). Instead we show a sketch of two polymer filaments (chains):

the chain drawn bold has one end attached to the fixed disk, and the other is closer to the rotating disk. This filament is stretched, and exerts a pressure upon the second filament, which is on the side nearer the center. Try to apply this reasoning as an explanation for the swell at the die extruder!

@TEC: 3. 3.2003 Change language to