|

Department of process engineering U218

Research project: Waffle baking

|

|

Preface and links:

Project "Hydrophobierung and biologische Abbaubarkeit

von Materialien aus nachwachsenden Rohstoffen" ,

was initiated in 1996 at TU Dresden,

Institute fur Lebensmittel und Bioverfahrenstechnician

by Prof.Lothar Linke.

This project is a good example of cooperation between Germans (TU Dresden

/supervisor/, Ingenieurburo dur Nahrungsgutertechnician

IBN GmbH Dresden) and Czechs (

ICT Prague, and

CTU in Prague).

The project is supported by Deutsche Bundesstiftung Umwelt

.

Our contribution is oriented on the mathematical modelling of the process of waffle baking:

- Process description

- Mathematical models

- Parametric identification

- Results

- Technological impacts and open questions

Abstract:

Physical models describing baking of the starch based biologically

degradable products (dishes, packages, etc.) are suggested and verified

by experiment.

Suggested pressure baking technology is similar to the contact heating

of waffles in a toaster: raw material - water suspension of starch

and additives (e.g. cellulose) - is placed into a closed planar mould and

heated by contact with walls having a constant temperature.

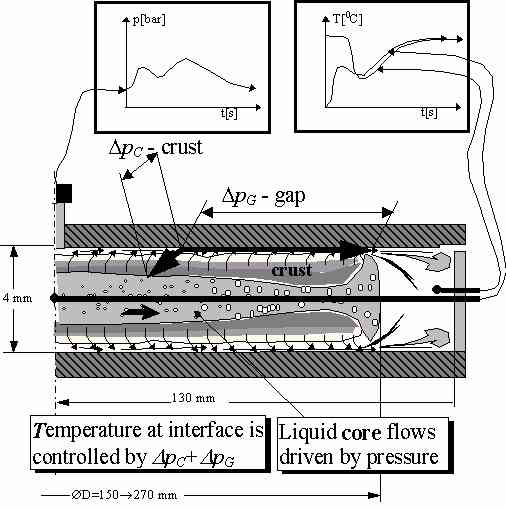

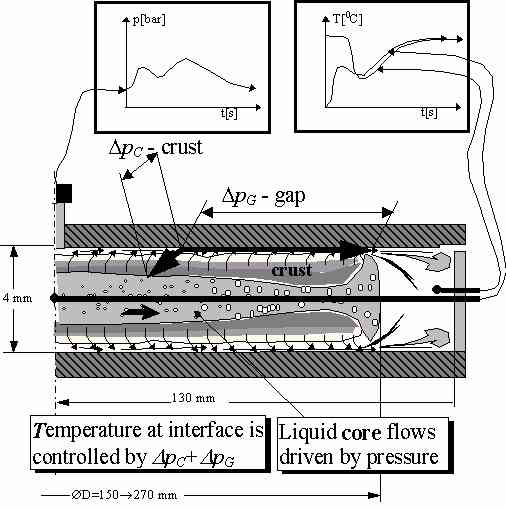

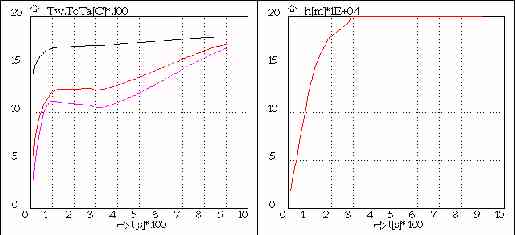

The time courses of temperature, measured at the centre of the narrow gap

between the walls (the gap thickness is only 4 mm) exhibit a local

maximum - suspension temperature increases to cca 120-1400 C,

then decreases and only after some time monotonic rises to the wall

temperature 1800 C! Also the pressure, measured at the centre

of the heated sample is characterised by one or two distinct peaks of

about 2-3 bars. Crust and core models try to explain these non-usual

phenomena assuming that the boiling temperature of free water -

and thus the temperature of suspension- is controlled by the pressure

of the evaporated steam. Three phases of thermal processing are

analysed separately:

- The first phase is heating of a more or less

homogenous layer of water suspension up to the onset of boiling.

- The second phase is characterised by evaporation of free water and by

formation of a growing solid crust. At the same time the liquid core

expands, driven by pressure of steam, which leaves the crust-core

interface and flows through the porous crust and along the walls of

the mould. The friction loses in the crust and in the interstitial

spaces at the wall determine pressure at the crust-core interface,

and are manifested as the first peak of recorded pressure.

- When the crust is fully developed and the expansion stops, the

last phase of heating, accompanied by the evaporation of the remaining

bound water, begins. The sample temperature no longer depends on

the boiling temperature and steadily approaches the temperature of wall.

The second peak of pressure that was sometime observed can be ascribed

to the non uniform distribution of pressure along the surface of sample.

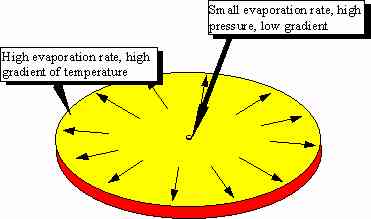

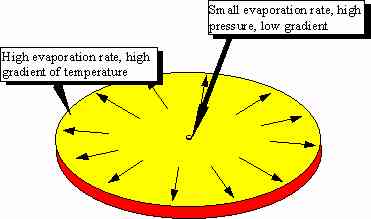

The lowest pressure (approximately atmospheric pressure) must be at

the periphery, but a low pressure means a low temperature of boiling,

therefore a large difference between the temperature of wall and the

temperature of the crust-core interface. Thus the temperature gradient

and the crust growth rate is greatest at the periphery of the

baked sample and just there the solid crust is soonest developed.

This firm peripheral crust closes the remaining liquid suspension inside

the sample and prevents its further expansion, which causes the pressure

increase.

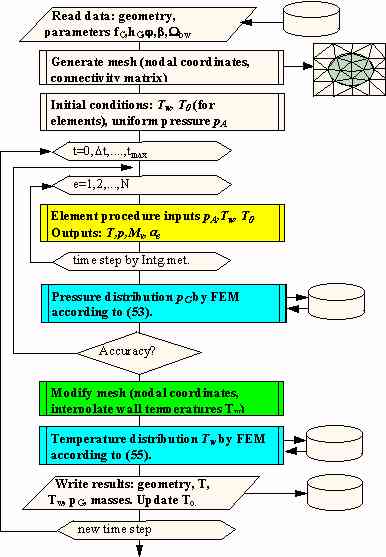

Mathematical models

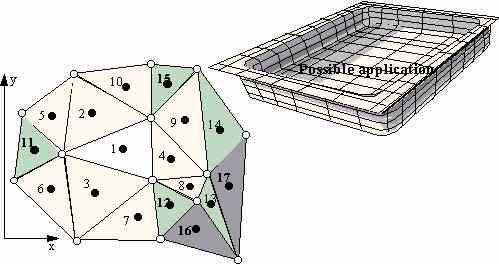

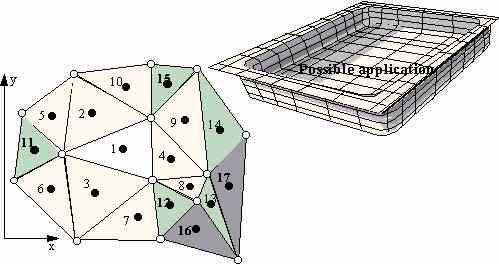

Simplest mathematical models are crust-core integral models,

describing the whole sample

in terms of mean temperature, mean pressure, volume of sample and

mean thickness of crust as functions of time.

This integral model forms a basis for the shell element, which can

be used in a finite element program,

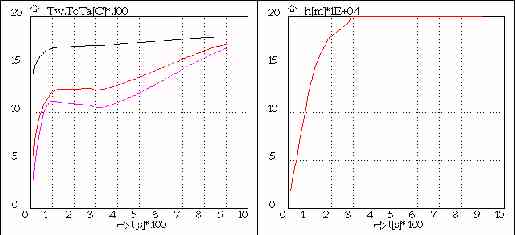

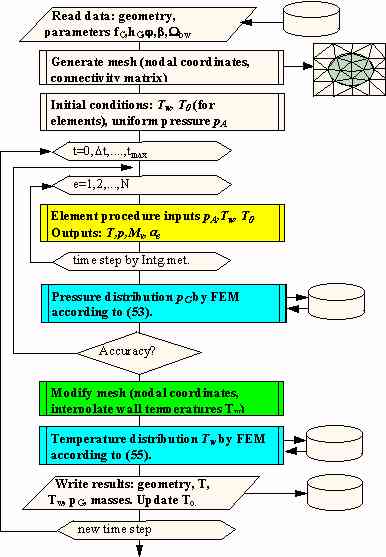

More details, concerning transversal temperature, pressure and moisture profiles, are

obtained by two dimensional models using finite difference methods. Some results

(temperature and crust thickness as functions of time) are

shown in Fig.

Technological impacts and open questions

Even if the theoretical analysis and numerical simulation of baking process has not been fully completed and a match with experimentally measured data is not excellent, some conclusions can be drawn:

- Baking process depends significantly on the amount of bounded water and on the strength (energy)

of water-solid bond. Therefore useful information about the influence of raw material properties

(composition of suspension) on the baking process can be obtained from drying curves (drying experiments).

-

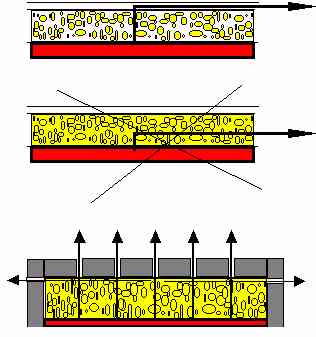

Pressure of evaporated steam is significant and has to be respected even in the simplest model of mould baking.

-

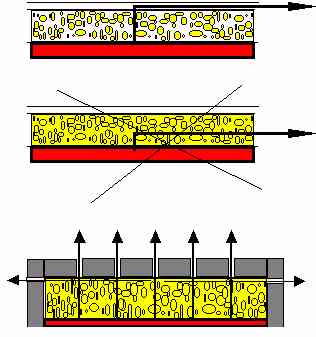

Pressure drop is determined by the path of escaping steam. There are two principal possibilities:

- Flow through the crust in the transversal direction and then through a narrow gaps - microchannels - along the heating plate.

- The second possibility is that the steam flows prevalently in the longitudinal direction

through the porous crust.

Numerical models indicate on the basis of comparison with experimental data,

that the second mechanism - steam leaving the waffle in the longitudinal direction - is improbable.

If it would be so, the time courses of pressure should exhibit very fast initial growth and this phenomenon

was not observed. This conclusion is only preliminary, and should be verified experimentally.

However, if it is true, the properties of mould surface /roughness/ have to be significant.

It would offer many possibilities how to improve uniformity of baking by some technical and technological

means, e.g., by using perforated or wrapped contact surface, thus allowing steam to leave the crust

without significant increase of pressure and temperature during the second phase of baking

(free water evaporation).

- Numerical experiments indicate, that the product is baked most intensively near the periphery and

not at the centre (the evaporation is faster in the part, where the pressure of steam is lowest).

This could explain the strange second peak of pressure, that was observed in some experiments.

It seems that this effect can be a limiting factor of the processed product size.

- Mathematical models enable to predict the baking time and its dependence on the thickness

and other geometrical parameters of product.

This project is far from being finished, and the research, coordinated by TU Dresden

continues.

@TEC: 3. 3.2003

Change language to

peoples

peoples

mailto: Zitny

mailto: Zitny