We offer various services in our department including consultations and courses. The examples are listed below. Please contact us for more information.

Material tests

The tests can be performed under strain and stress control for plain and notched specimens with possible utilization of digital image correlation for various materials. The induction heating system allow us to test various metallic materials and metal matrix composites including aluminium, copper and nickel based alloys at elevated and variable temperatures. |

Life prediction

The life prediction analysis can be performed for isotropic materials, anisotropic materials, additively manufactured materials and composites. We can utilize finite-element analysis results to calculate and visualize damage variables for complex components. |

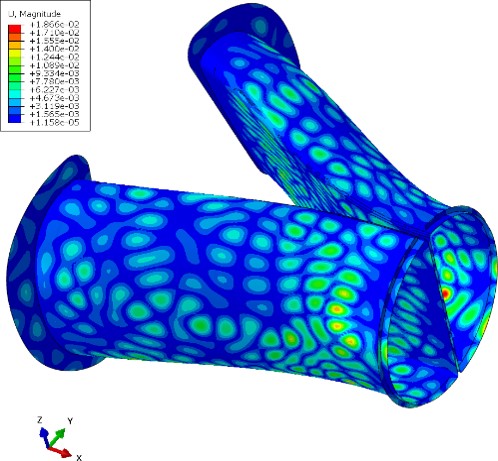

Finite-element analysis

|

|

Machine learning

|