Theory

- Jiří Fürst

Table of contents

- 1. Mathematical model

- 1.1. List of symbols

- 1.2. Velocity triangles for turbines and compressors

- 1.3. Streamline curvature method

- 1.4. Solution at the inlet section

- 1.5. Solution in free passage

- 1.6. Solution in bladed passage

- 2. Thermophysical models

- 2.1. Perfect gas

- 2.2. Aungier-Redlich-Kwong

- 3. Empirical loss and deviation models

- 3.1. Lieblein’s model

- 3.2. Aungier’s AMDC-KO model for turbines

1. Mathematical model

The calculation is based on the streamline curvature method. The solution is calculated in the meridional plane along the so-called quasinormals corresponding to the inlet section, leading and trailing edges, and the outlet section. The solution along a quasinormal is obtained by the solution of radial equilibrium. Effects of blade rows are included by appropriate empirical models.

1.1. List of symbols

- - the absolute velocity magnitude, in (m/s)

- - the meridional velocity magnitude, in (m/s)

- - the circumferential velocity magnitude, in (m/s)

- - the relative velocity magnitude, in (m/2), note: for stator

- - the meridional velocity magnitude, in (m/s), note always

- - the circumferential relative velocity magnitude, in (m/s)

- - the pressure, in (Pa)

- - the total pressure, in (Pa)

- - the total pressure in relative system, in (Pa)

- - the temperature, in (K)

- - the total temperature, in (K)

- - the relative total temperature, in (K)

- - the density, in (kg/s)

- - the enthalpy, in (J/kg)

- - the total enthalpy, in (J/kg)

- - the relative total enthalpy, in (J/kg)

- - the entropy, in (J/kg/K)

- - blade angles, in (deg)

- - flow angles, in (deg)

1.2. Velocity triangles for turbines and compressors

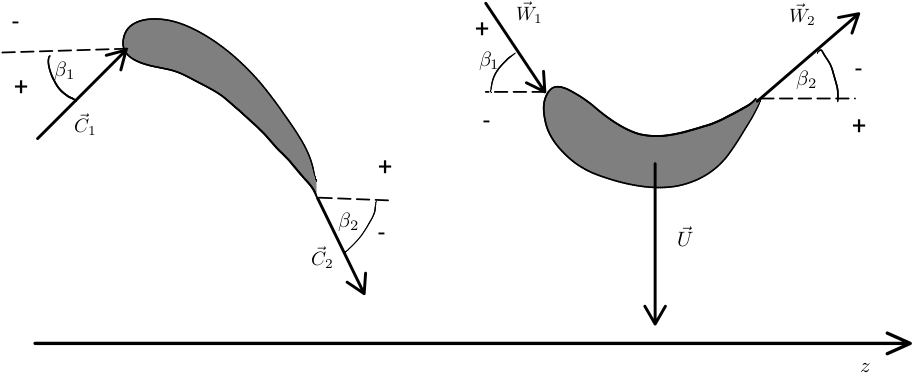

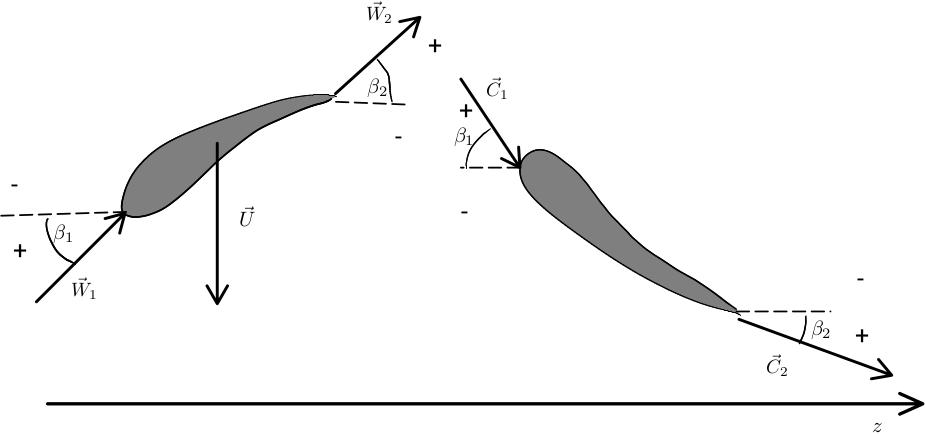

1.2.1. 1.2.1 Turbine convention

The orientation of angles in a turbine is follows:

- Stator row:

- Rotor row:

1.2.2. 1.2.2 Compressor convention

The orientation of angles in a compressor is follows:

- Rotor row:

- Stator row:

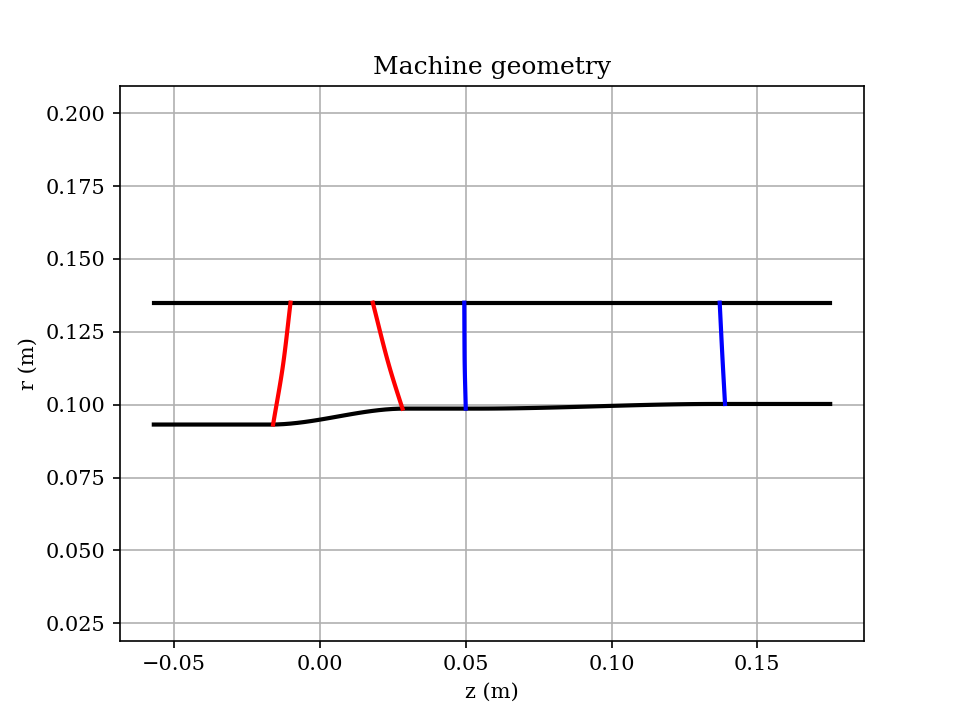

1.3. Streamline curvature method

The solution is sought in the meridional plane along quasinormals corresponding to inlet section, leading and trailing edges, and the outlet section.

The meridional view of single stage of a compressor is shown bellow. Red lines are the outlines of leading and trailing edge of rotor blades, blue lines are the leading and trailing edges of stator blades.

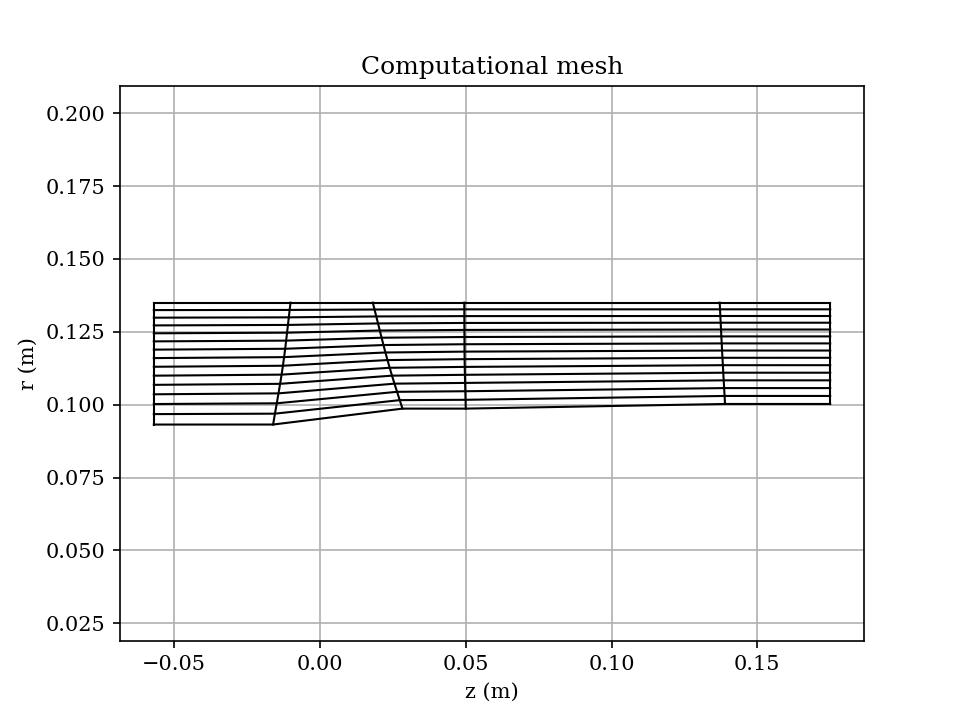

The computation is performed on a streamline aligned mesh shown bellow.

The actual shape of the streamlines is obtained iteratively during the solution process.

The actual shape of the streamlines is obtained iteratively during the solution process.

1.4. Solution at the inlet section

The flow field at the inlet section is considered in axial direction with given total pressure, total temperature, and the mass flow rate. The inlet velocity magnitude is calculated by solving the non-linear equation where is the total enthalpy at the inlet, is the inlet entropy, and is the annulus area. The other quantities are then evaluated using thermodynamic package.

In the next step the position of streamlines at the inlet section are setup in order to keep the same amount of the mass flux between two streamlines.

1.5. Solution in free passage

The solution in a free passage between and quasinormal is obtained using the conservation laws: where corresponds to streamline number.

The remaining quantities are obtained using the radial equilibrium equation. For details see e.g. Aungier

The position of streamlines along the quasinormal are then updated in order to keep constant amount of flux rate between two streamlines.

1.6. Solution in bladed passage

The solution at outlet edges is obtained with the help of empirical performance models. The model provides the deviation angle which is used for calculation of the flow angle at the outlet edge. Then, the following equations are used together with radial equilibrium: where is the rothalpy, is the outlet flow angle, and is the entropy increase calculated from the total pressure loss coefficient provided by the empirical model. For details see Aungier

2. Thermophysical models

2.1. Perfect gas

The perfect gas model assumes a compressible gas governed by the ideal gas equation of state The specific heat capacity at constant pressure is assumed constant.

The specific enthalpy is calculated as and the specific entropy as

Sound speed is with .

2.2. Aungier-Redlich-Kwong

The real gas model uses Aungier’s modification of Redlich-Kwong cubic EOS together with polynomial approximation of ideal gas contribution to $c_p$.

The Aungier-Redlich-Kwong eos is where

- is the specific volume,

- is a reduced temperature,

- is the user specified accentric factor,

- ,

- ,

- ,

- is calculated from EOS at the critical point,

- are the critical temperature, volume, and pressure.

The ideal gas of is given as a polynomial of temperature :

Then, the ideal gas contribution of enthalpy and entropy are Integration constants and are chosen in such way that the values of enthalpy and entropy (including real gas contribution, see bellow) match the values at given reference state.

The real gas contribution (departure functions) are where .

The value of , , and is then

3. Empirical loss and deviation models

The loss and deviation model uses compressor nomenclature depicted in the following figure.

Here:

- is the geometrical angle at the inlet edge (in degrees)

- is the geometrical angle at the outlet edge (in degrees)

- is the flow angle at the inlet edge (in degrees)

- is the flow angle at the outlet edge (in degrees)

- is the stagger angle (in degrees)

- is the blade chord

- is the cascade stagger

These quantities define following parameters:

- - the incidence angle (in degrees)

- - the deviation angle (in degrees)

- - the cascade solidity

- blade camber angle (in degrees)

3.1. Lieblein’s model

Lieblien’s model is implemented according to

AUNGIER, Ronald H. Axial-flow compressors : a strategy for aerodynamic design and analysis. B.m.: ASME Press, 2003. ISBN 9780791801925.

The model is originally developed for compressor cascades with NACA 65 profiles.

3.1.1. Loss model

Lieblein’s loss model calculates the design incidence angle as where is the shape factor ( for NACA 65 profiles), is the blade thickness correction, is the zero camber incidence, and is the slope factor. These parameters are calculated as

The design total pressure loss is where , , and with and for NACA 65 profiles. The equivalent diffusion factor is defined as

The off-design loss model is then corrected for incidence angle and Mach number effects, see Aungier’s book, chapter 6.

3.1.2. Deviation model

The design deviation model has the form where is the shape factor same as for the design incidence model, is the thickness correction, is the slope parameter, and is the zero camber deviation.

According to Aungier’s book, the parameters are calculated as where ,

with .

Note that the correlation for depends on the profile family and the presented correlation is for NACA 65 family. Therefore can be configured in the input file.

The off-design correlation is then where

3.2. Aungier’s AMDC-KO model for turbines

Note

The model is described in Aungier’s book Turbine aerodynamics: Axial-flow and radial-inflow turbine design and analysis, chapter 4. Although the original model was formulated for angles in turbine convention, the Turana software uses consistently angles in compressor convention (see above). Therefore it is necesaary to convert angles from turbine convention to compressor convention. The conversion is done as follows:

The outlet geometric angle corresponds to throat by pitch ratio, i.e. .

3.2.1. Loss model

Total pressure loss in turbine cascade is defined as

The current version supports only the model of profile losses and losses caused by the non-zero thickness of the trailing edge, hence

The model for profile loss is for details see Aungier.

The trailing edge loss is modeled as where $te$ is the trailing edge thickness.

3.2.2. Deviation model

The subsonic deviation angle for is calculated as

The deviation for for is calculated as with .

In the case of supersonic outlet the deviation follows from the conservation of mass where and are the density and velocity magnitude in the sonic point.